5 Reasons Why Laser Welding is the Optimal Choice for Your Next Welding Project

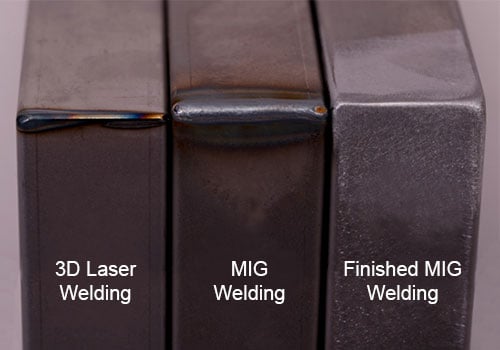

During both MIG and TIG welding operations, residual spatter can — and often does — occur on the workpiece. In addition, both of these processes usually add filler metal to the weld joint. This excess material must be removed, generally through grinding or similar finishing processes, before the part goes on to further processing operations or into use.

By contrast, laser welding employs such a focused, brief application of heat that there is virtually no spatter or material buildup. This quality streamlines the manufacturing process for laser-welded parts as the pieces do not need to undergo post-welding grinding or other finishing operations and can proceed directly to painting and/or assembly.

Get even more proof of why 3D laser welding is the optimal choice in the ebook >>>